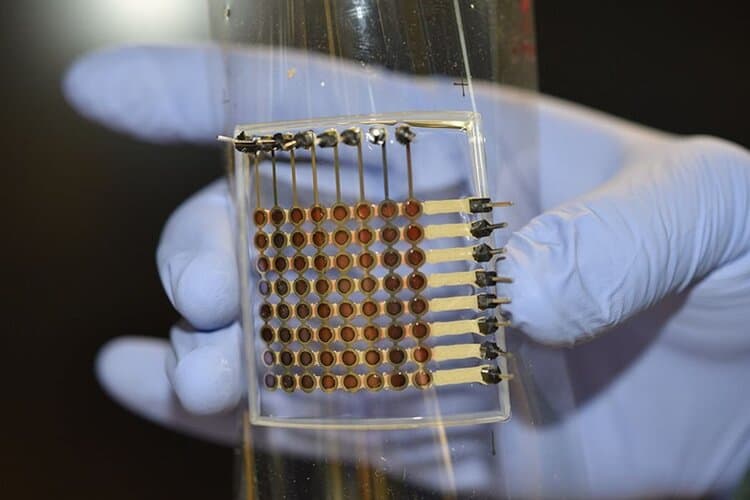

Researchers at the University of Minnesota have developed a unique method for 3D printing a flexible OLED display prototype.

Michael McAlpine of the University of Minnesota’s Department of Mechanical Engineering, one of the paper’s authors, explains why this technology was developed:

“OLED displays are usually produced in big, expensive, ultra-clean fabrication facilities. We wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.”

A Model S would cost between US$88K and US$124K, making it somewhat more costly than average desktop 3D printers. However, this is a fraction of the cost of a normal OLED panel production factory. 😅

Make sure to check the video to see how it works:

The prototype OLED panel, as you can see in the video works, but has a very low resolution. That’s because they’re only showing off the technology, not making a commercial product. This is a step that must be taken before the product can be sold.

Another way this technology could be used is to add it to 3D printing. Assume that there is an OLED display or lighting that can be printed, as well as a mechanical structure that can be built. That’s very close to being able to 3D print fully functional electronic objects.

What do you think of this one?