Sam Zeloof is not a typical 22-year-old undergraduate student, he is a self-taught silicon chip designer who has already produced two handmade silicon chips.

Guess when did he make his first chip, the Z1, in 2016, while still a high school student. What?!

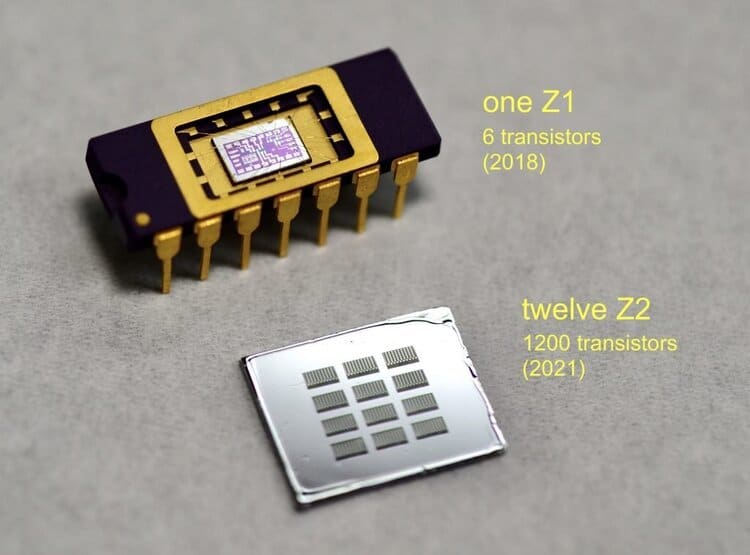

The Z2, his second chip, features a quicker switching transistor architecture based on polysilicon wafers. It is composed of a grid of 12 circuits, each with 100 transistors, for a total of 1,200 transistors.

The Z1 contained six transistors and was an excellent development chip for all processes and equipment.

Previously, he used a metal gate process to create chips. The aluminum gate’s work function is significantly different from that of the silicon channel beneath it, resulting in a high threshold voltage (>10V). He used these metal gate transistors in a few interesting projects, including a guitar distortion pedal and a ring oscillator LED blinker, although both required one or two 9V batteries to operate due to the circuit’s high Vth. By moving to a polysilicon gate technique, he gains a slew of performance improvements (self-aligned gates result in lower overlap capacitances), as well as a significantly lower Vth, which allows these devices to operate at 2.5V and 3.3V logic levels.

He has so far created an opamp (Z1) and a memory-like array (Z2). Even with this low transistor density, more intriguing circuits are undoubtedly conceivable. The technique requires some fine-tuning, but now that he can produce high-quality transistors on a continuous basis, he should be able to construct more intricate digital and analog circuits. Testing each chip is time-consuming, so he’s working on automating the process and will release additional data once he’s done. He’s created 15 chips (1,500 transistors) and knows there’s at least one fully working chip and at least two “largely functional,” which means 80 percent of the transistors operate rather than 100 percent. There is no adequate yield data yet. The most prevalent problem is a shorted drain or source to the bulk silicon channel, rather than a leaky or shorted gate, as on his Z1 technology.

Sam Zeloof said that now we know that it’s possible to make really good transistors with impure chemicals, no cleanroom, and homemade equipment.

Check out the whole video for more details.