We use microchips in our daily lives, but I’m sure you’re wondering how they’re made. Let’s find out!

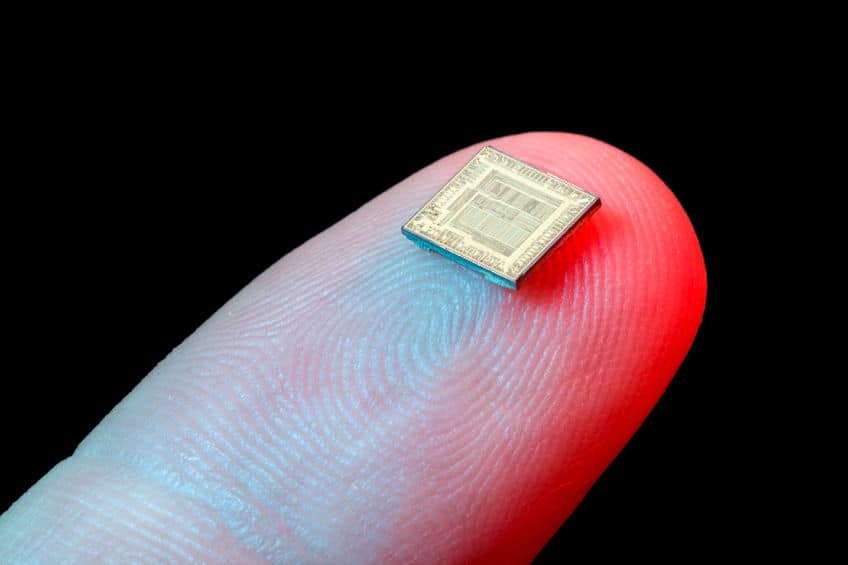

Microchips can take up to 26 weeks to manufacture under typical conditions since they pack as many as 100 layers of billions of transistors onto a space the size of a fingernail. They are created using silicon-rich sand. As we all know silicon is a semiconductor whose characteristics may be adjusted by doping it with impurities to match the requirements of various electrical devices.

The way a chip operates is determined by the design of the transistors and gates on the chip and the chip’s intended application. Schematics—symbolic representations of the transistors and interconnections that regulate the flow of electricity through a chip—are created using design parameters such as chip size, transistor count, testing, and manufacturing considerations.

After that, designers create stencil-like patterns, referred to as masks, for each layer. Designers conduct detailed simulations and test the chip’s functionalities using computer-aided design (CAD) workstations. Hundreds of workers are required to develop, test, and fine-tune a chip before it is ready for production.

The “recipe” for fabricating a chip changes according to the intended usage of the chip. Chip fabrication is a complicated process involving hundreds of highly regulated processes that result in patterned layers of diverse materials stacked one on top of the other.

On a wafer, the multilayered transistors and interconnects (electrical circuits) of a chip are formed using a photolithographic “printing” process. On a single silicon wafer, hundreds of identical CPUs are manufactured in batches.

Once all of the layers are complete, a computer runs what is known as a wafer sort test. The testing verifies that the chips function according to the standards specified during design.

Following fabrication, it’s time to package. The wafer is split into little pieces known as dying. A finished processor is formed by sandwiching the die between a substrate and a heat spreader. When installed directly into a computer circuit board or mobile device, such as a smartphone or tablet, the packaging covers the die and provides the necessary power and electrical connections.

For more details make sure to watch this great video