At Ohmify, we love seeing our members learn new things and engage with the community. Today, we want to introduce you to Mark Kendle – one of our longstanding members.

Mark loves to cycle, repair things electrical, play with model trains, and is a valuable member of our community.

Where are you from, and what do you do?

I have always lived and worked near the same city where I was born which is Southampton in England. This is a great location on the South Coast because it is quite central for easy access to the coastal beaches, the New Forest, and the infamous Jurassic Coast. Not so good if you are keen on our premier ship football as our local team Southampton face relegation this season.

I am 62, married with 2 grown-up sons. I have done a number of jobs over the years but I guess my trade is as a mechanical /design engineer. I work for a company who manufacture specialised mechanical bearing systems (linear bearings, Ballscrew Drives, Actuators.) that are used in a wide range of automated machines and robotics. My Job is to work with our customer’s design engineers and recommend solutions to their machine design problems using our products.

Life is busy as I play cricket during the summer months so not much gets done from May to August, well that is what my wife will tell you! I love to cycle, explore the countryside, repair things electrical build Ohmify projects, and play with Model Trains.

What was the main reason you joined Ohmify?

I had been playing around with electronics for a number of years, mostly learning by repairing or trying to repair stuff that had broken. The main reason for joining Ohmify was that I felt that there was no structure to what I was learning and that there were a lot of gaps in my knowledge.

I couldn’t see myself having time to go college to learn electronics so I began like many to search the net for the info that thought I needed without a lot of success and then I came across Ohmify’s free e-book 10 Simple Steps To Learn Electronics – The ebook put things into perspective and it became clear to me what I needed to learn and from who. After a short time, I signed up to Ohmify. This is my 3rd year.

Are there any projects you’ve completed since joining Ohmify that you couldn’t have completed before?

I have completed a number of Ohmify projects using the Arduino. What an eye opener these have been. I hadn’t heard of Arduino before joining Ohmify and yet now I can use this remarkable piece of kit in my own designs and projects.

What is the most fun project you’ve ever worked on?

My real electronic passion is repairing things. The project that was the most fun also had the greatest impact on me. It was the repair of my broken Peavey Guitar amp some years ago. I managed to diagnose which part of the circuit board was most likely to be the problem and thru visual inspection I could see a damaged transistor. I needed to replace the transistor but found out that it was no longer available. I remember having to look up the equivalent model, checking the data sheet and then soldering the replacement in place. I powered up the amplifier with some trepidation and wow!! it worked!!

Looking back It seems such a simple thing to do but I hadn’t done anything like that before and for me it was an unbelievably satisfying feeling.

What is your favorite thing about being a part of Ohmify?

Having access 24/7 to some of the best courses and projects out there. Plus the support from the team and other Ohmies when the going gets tough.

What are you currently working on?

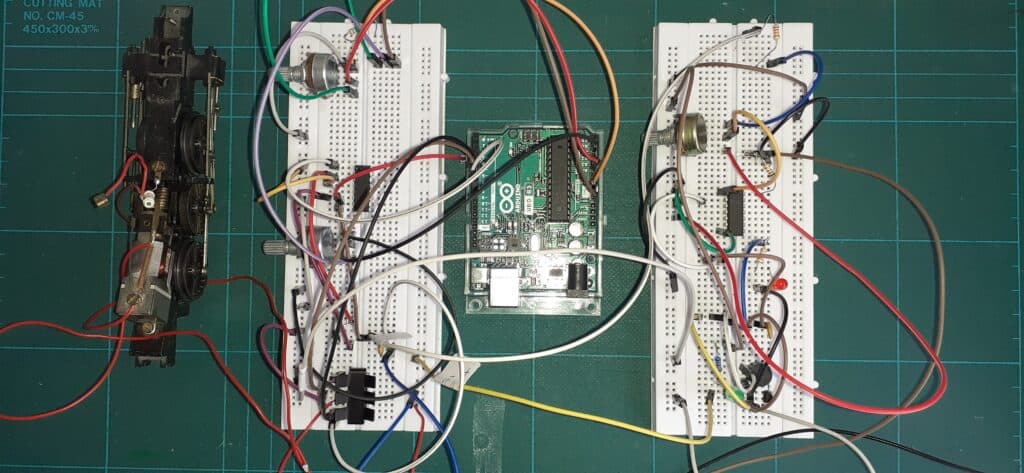

My current project is a dual track model railway controller. I am using the Arduino Uno to drive up to 2 DC motor controlled locomotives via a L293D motor driver chip. Short circuits are a big issue with model railways and most commercially available controllers will have some degree of short circuit protection via a Thermal Resettable Fuse. I wanted to go a step further because that type of protection is good for the controller but not so good for the model locomotive. Time is of the essence and the sooner you are aware that there is a short circuit the better and the more likely that the locomotive motor will not be damaged.

My idea was to have audible and visual warnings as well as protecting the controller. I had completed the Introduction to Digital Electronics course a while back and this gave me the idea of how to solve this problem in my design. I now have short circuit detection/protection using a thermal resettable fuse but the fuse works in conjunction with an inverter chip which controls a NPN transistor circuit powering a warning buzzer and red LED. The controller has been built onto a breadboard and tested ok but it does look very untidy. I guess I could build the circuit onto a stripboard but I decided to design the PCB myself and have it made thanks to KiCad.

We’re grateful to have you as a member, Mark!

Stay tuned for more interesting stories about our members in the future.